Life sciences

ALTEN develops and delivers Life Sciences expertise to world-leading companies. Today ALTEN is a key player in Life Sciences: Pharmaceutical, Biotechnology and Medical Devices, with more than 30 clients.

Our clients vary from large pharmaceutical companies to smaller actors in Life Sciences. As a global player with a local presence, we are flexible and able to adapt to the needs of every single customer.

Activities

Quality Management and Regulatory Compliance are core business processes within Life Sciences. As listed in EudraLex, the pharmaceutical industry of the European Union maintains high standards of quality Management in the development, manufacture and control of medicinal products. A system of marketing authorizations ensures that all medicinal products are assessed by a competent authority to ensure compliance with contemporary requirements of safety, quality and efficacy.

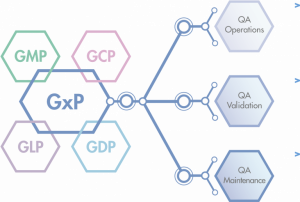

GxP is a collection of quality guidelines and regulations created to ensure that bio/pharmaceutical products are safe, meet their intended use and adhere to quality processes during manufacturing, control, storage and distribution.

Compliance with GxP rules is decisive for ensuring that end customers have access to high-quality products, which is why all pharmaceutical industry operations must be performed in accordance with GxP requirements.

ALTEN supports its customers throughout the product lifecycle, offering tailored solutions in all GxP areas:

GxP Areas ALTENGuarantees that production acitivites are performed and documented according to GMP requirements and quality systems (change control, deviation, CAPA etc.)

Ensures that activities related to equipment qualification and process validation are performed and documented according to GMP and quality requirements.

Provides that technical service activities (calibration, metrology, utilities management etc.) are performed and documented according to GMP and quality system requirements.

ALTEN guides, leads or supports its customers through the following activities:

- Preparation and assistance with audits (pre- and post-audits)

- Handling of deviations

- CAPA monitoring and management

- Follow-up and handling of customer complaints

- Authoring and implementing SOPs

- Evaluation and design of staff training programs

- Periodic Quality Reviews

ALTEN supports its customers throughout the qualification and validation cycle in compliance with EUDRALEX Annex 15. Our engineers and pharmacists are experts in the V-cycle and ASTM E2500 validation methodologies.

ALTEN has also proven experience in delivering CSV projects for pharmaceutical companies and is fully qualified to meet clients’ requirements, complying with the applicable regulations (e.g. 21 CFR part 11).

ALTEN assists its customers in the following activities:

- Definition and implementation of validation/qualification methodologies. (VMP, VP, etc.)

- Planning and coordination of validation/qualification activities.

- Implementation of validation/qualification SOPs in Quality Management Systems.

- Designing (templates for) qualification and validation documentation. (Reports, protocols, etc.)

- Performing and managing equipment’s’ qualification, process validation and training of personnel. (IQ/OQ/PQ).

- Creating and running process validation groups.

- Promoting a scientific risk-based approach for a compliant validation and qualification program.

Our consultants provide support throughout the validation/qualification process in manufacturing & laboratory environment:

Equipment

- Filling lines, bulk, formulation areas

- Purification, (ultra) filtration

- Dry form equipment (tableting machine, powder mixer, granulation…)

- Laboratory instruments (chromatography, spectroscopy,…)

- Controlled storage (incubators, stability chambers, cold storage)

- Packaging and labelling

Process

- Product manufacturing

- Aseptic process

- Cleaning (CIP, machine, sinks)

- Sterilisation (autoclaves)

- Analytical methods

Utilities

- HVAC, Laminar Air flows

- WFI, PW

- ACP

- CSV

- ERP (SAP, Microsoft Navision)

- LIMS

- Document Management Systems and other QMS applications (e.g.: Deviation, CAPA Systems, etc.)

- Manufacturing equipment

- Automation systems

- Laboratory Equipment

Continuous manufacturing presents growing challenges, whatever the galenic form of your product, from capsules, solutions, suspensions, emulsions, gels, creams to aerosols….

ALTEN supports its customers with the following activities:

Deviation Management:

- Managing root cause investigations

- Assessing potential impact on product and GMP activities

- Defining and implementing corrective and preventive actions

- Continuous improvement in order to reduce recurrent deviations to arise.

Industrial Excellence:

- Assessing and evaluating existing processes and defining potential improvements

- Implementing actions to decrease waste and improve the reliability and efficiency of the operational process

Sterility Assurance:

- Assessing and improving activities linked to environmental monitoring and aseptic practices

- Implementation and follow-up of a relevant monitoring, defined with risk approach

Our activities area concerns the following sectors:

Technical Services:

- Clean utilities (HVAC, ACP)

- Black utilities (steam)

- Shutdown management

Devices:

- LAF, RABS and isolators

- CIP/SIP

- Filling lines, bulk, formulation areas

- Purification, (ultra)filtration

- Dry form equipment (tableting machine, powder mixer, granulation…), liquid form equipment

- Packaging

From its design to its operation, and of course through its commissioning, a pharmaceutical production site requires mobilisation of all engineering facets.

ALTEN supports its customers through the following engineering activities:

- Design: feasibility studies, basic and detailed design.

- Commissioning equipment installation management in accordance with user requirements – start-up, settings and initial functional tests on equipment.

- Excellent maintenance: optimisation of maintenance activities, definition and implementation of good practices in technical services.

- Reliability: GMP and EHS risk management applied to operations and maintenance of equipment activities & resources optimisation and planning.

The consulting teams of ALTEN assist in all these engineering roles:

- Project Manager

- Project Engineer

- HVAC

- Electrical

- Mechanical piping

- Civil & Structural

- Process Engineer

- Automation Engineer

- Draughtsman

- MES Analysts & Developers

ALTEN Life Sciences’ division also provides its expertise in transversal activities such as Quality Control.

In the laboratory, ALTEN provides its support in the following activities:

- Scientific analysis

- Validation of analytical methods

- Analytical development

- Methods development

- Methods transfer

- Analytical transfers

- Project Management