IoT – based data – driven solutions Bits & Chips magazine ALTEN published an article on ‘Infusing the mobile-crane industry with IoT-based data-driven solutions’ written by consultants Martijn Lemmen and Jan Eefting:

Spierings changed the construction industry as early as the 1980s by putting a collapsible tower crane on wheels. Now, they’re the first in the industry to provide their customers with data-driven services allowing interaction with the crane over the internet.

Complex machines such as mobile tower cranes contain a vast amount of technical subsystems, each pertaining to specific functionality. Within this collection of decentralized subsystems resides a wealth of data that reflects the state of the machine at any given point in time. However, the value of this data hasn’t yet been fully realized because data could only be retrieved by physically extracting it from the crane onto a thumb drive.

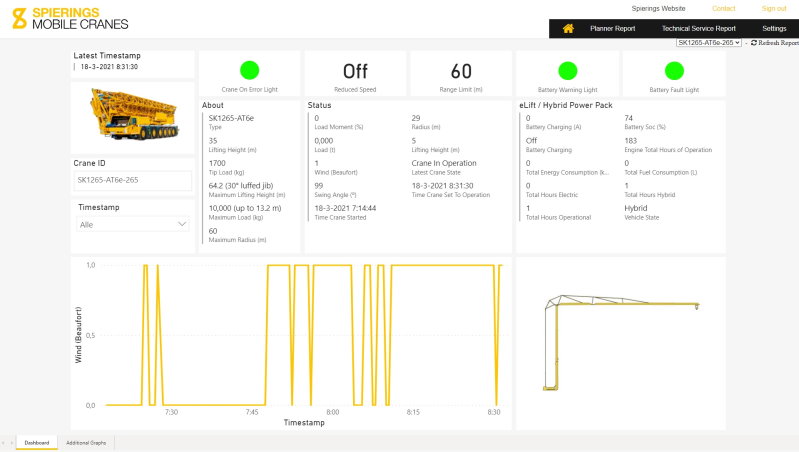

By making the data available in real-time, new possibilities for process improvement arise. Planners have accurate real-time data to inform operations and can resolve on-site disputes such as whether to halt operation because of strong winds by comparing precise wind measurements to wind speed danger thresholds. Technical staff has immediate insight into the crane’s current or last known state, enabling more effective remote assistance provided to crane operators.

Cranes manufactured by Spierings are often rented out by the proprietor along with a skilled operator. A crucial part of the rental agreement is the maximum length of the boom. This determines the maximum range at which weight will be lifted and heavily impacts the rental rates. Here, it’s important to note that the further away something is lifted, the larger the strain on the crane becomes, thus increasing wear and reducing the effective lifetime of the crane.

Operators are informed of the agreed-upon maximum length. However, physically enforcing this limit isn’t trivial. So, operators unwillingly become responsible for the enforcement and, as a result, often get involved in commercial discussions and potentially risk non-compliance with the rental agreement. To remedy this, we provide the owner the ability to remotely limit the maximum length. This way, he’s sure his rental rates are protected while the crane operator isn’t burdened with commercial discussions and undesired responsibilities.

ALTEN was challenged with fitting the mobile tower crane with a secure two-way connection to the cloud. The goal was to make it possible to capture live data generated within the machine and turn it into value in real-time, while also enabling the crane to remotely receive configuration updates such as setting limitations to the length of the boom.

Device twin

The concept of real-time data-driven services that can be used by non-technical personnel is new and relatively untested within the mobile-crane market. As an innovation project, Spierings decided to take the first steps to validate the feasibility of the endeavor using a limited budget and scope. For us, this meant getting things done within a short timeline and with limited resources.

A major requirement for Spierings is the ability to retrofit existing cranes with the new solution without requiring modifications to existing hardware. As a solution, we’ve introduced a computational unit responsible for running custom software enabling communication with crane subsystems and coordination with remote services. It needs to be small enough to be able to ship to remote clients and sturdy enough to deal with the stringent usage requirements. Note that the cranes are already fitted with a mobile internet connection and internal network.

Spierings planner report

The majority of the IoT devices on the market today are small computation units for the commercial and consumer markets, such as a Raspberry Pi. These devices, however, have severe limitations regarding lifespan under heavy sustained usage, whereas we required a sturdy industrial unit able to function for extended periods in harsh conditions. After evaluating hardened versions of a Raspberry Pi, we finally settled on an industrial PC (Phoenix Contact BL2 BPC). This IPC was selected in part for its form factor, hardened electronics, performance specifications, as well as its support for major Unix operating systems, which in turn run almost any custom software that may be required.

Azure was chosen as the cloud vendor because of the extensive number of (IoT) services offered as well as their maturity. The Azure IoT platform, specifically the IoT Edge services, supports custom containerized applications called modules. These modules can be deployed to physical devices remotely. They can be developed using a wide range of languages, including C, C#, Java, Node.js and Python – for this project, we picked C#.

Each device is configured and outfitted with an agent that coordinates between device and cloud and is mirrored in the cloud environment using a virtual ‘device twin.’ All communication, configuration and mirroring are done via the Azure IoT Hub. This hub acts as the repository for device settings and monitoring as well as a secure interchange for two-way communication. Changes to device configuration and modules are first deployed to the device twin. When the physical device connects to the IoT Hub, the agent retrieves and applies the latest configuration and runs the required modules.

Trickier

Once the IoT device is in place and operational, the crane is capable of transporting data beyond the physical system. The physical device opens a secure connection and then sends telemetry data to the IoT Hub every second, which is then handed further down the processing chain via Streaming Analytics. Data is subsequently stored for analysis and predictive purposes and a subset is collected in a database to be used in real-time reports and dashboards.

Besides disseminating telemetry data, we also need to securely send and read crane configurations, eg to enforce the agreed-upon boom length. This is slightly trickier. Although the uptime is high, there’s no guarantee that the crane has an active connection or is reachable at any point in time. Simply sending out a message with the new configuration, or sending out a message asking for the current configuration, won’t suffice.

To solve this, we used the functionality to store configurations as provided by the device twin to enforce custom configurations. The physical device is immediately notified of changes to this configuration and then retrieves and applies them. Even when it’s offline for some time, it will fetch the desired configuration automatically when it re-establishes the connection to the IoT Hub. No configuration changes are lost and all devices will retrieve the latest configuration and apply changes.

Robust

All this functionality has been made available to non-technical users via a web portal with PowerBI integration. The portal provides reports and dashboards displaying insights into the state of the crane. It also allows authorized users to change the configuration of the machine, eg setting a maximum boom length.

We were able to develop and deliver a robust solution using modern technology and services. The solution unlocks value in real-time from previously untapped data sources and provides crane operators and owners with vital insight into and control over the crane. It also allows incremental improvements and additions to functionality to be added over time to a stable and secure base.

Main picture credit: Spierings

Edited by Nieke Roos